Are you looking to start a career in welding?

During a welding certification program, you will learn various welding processes and techniques, as well as safety protocols and welding codes and standards. You will also have the opportunity to practice your welding skills and be evaluated on your performance. Successful completion of a welding certification program will earn you a welding certification in the specific welding process or processes that you were trained in.

Training to become a certified welder may be the next step for you. To become a certified welder, you will need to complete a welding certification program. With our training program, we allow you to gain on-the-job training and experience.

Welding Inspection

The purpose of welding inspection is to determine if a weldment meets the acceptance criteria of a specific code, standard, or other document. The welding inspector must be thoroughly familiar with welding processes, welding procedures, welder qualifications, materials, the limitation of weld testing, be able to read drawings, prepare and keep records, prepare and make reports, and make responsible judgments.

Non-Destructive Testing

What is non-destructive testing?

(NDT) Non-Destructive Testing is defined as various methods that are used to test a part, material, or system without impairing its future usefulness.

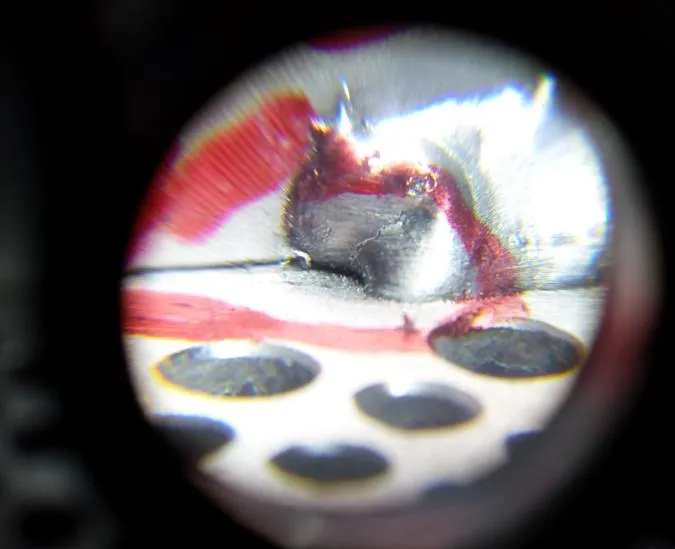

Visual Inspection

Visual testing is the observation of a test object, either directly with the eyes or indirectly using optical instruments, by an inspector to evaluate the presence of surface anomalies and the object’s conformance to specification. Visual testing should be the first nondestructive test method applied to an item.

Liquid Penetrant Inspection

What is Liquid Penetrant Inspection?

Liquid Penetrant Inspection reveals discontinuities open to the surfaces of solid and nonporous materials. Indications of a wide variety of discontinuity sizes can be found regardless of discontinuity orientations. Liquid penetrants seep into various types of minute surface openings by capillary action.

Ultrasonic Inspection

Ultrasonic Inspection is a method where beams of acoustic waves at a frequency too high to hear are introduced into a material for the detection of surface and subsurface discontinuities. These acoustic waves travel through the material with some energy loss (attenuation) and are reflected and refracted at interfaces. The echoes are then analyzed to define and locate discontinuities.