Our company specializes in providing high-quality magnetic particle inspection (MPI) services to a wide range of industries, including aerospace, automotive, and defense. Our team of experts uses state-of-the-art equipment and techniques to deliver accurate and reliable results.

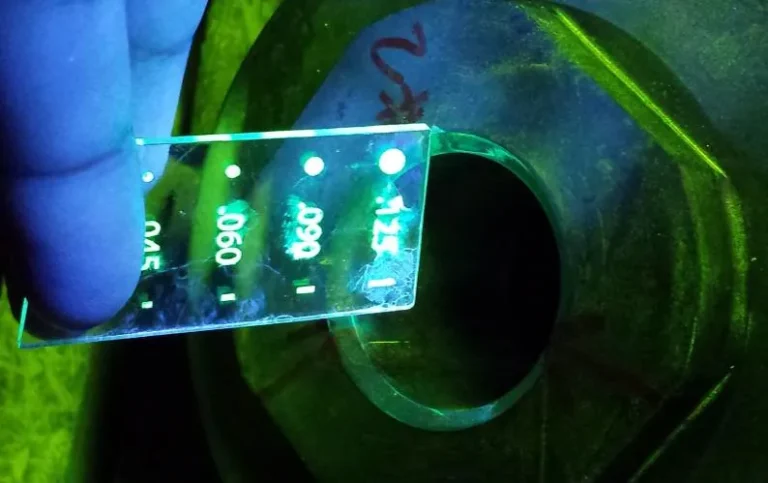

Magnetic Particle Inspection (MPI) is a non-destructive testing (NDT) method used to detect surface and slightly subsurface discontinuities in ferromagnetic materials. The process involves applying a magnetic field to the surface of the material and then applying magnetic or iron oxide particles to the surface. If there are any cracks, voids, or other types of discontinuities present, the particles will concentrate in these areas, indicating the location of the defect. MPI is commonly used in industries such as aerospace, automotive, and defense to ensure the quality and safety of components.